SIA pumps and controllers keep your wellhead producing and keeps costs contained with accurate control, power efficiency and reliability.

Keeping wells flowing and free from corrosion, scale and bacteria is possible with the accurate and reliable dosing capabilities of our chemical injection pumps.

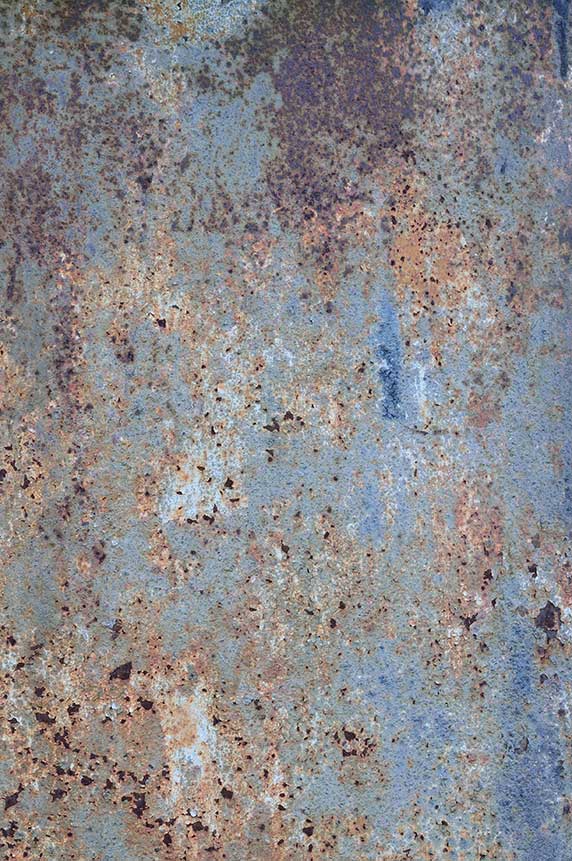

As the name suggests corrosion inhibitors act to limit or prevent corrosion in pipelines and other flow lines caused by reactions to environment.

Accurate dosing of application specific chemicals via an SiA chemical injection pump mitigates corrosion in wellbores, flow lines, transmission lines, gathering lines, and pipelines of oil and gas systems to preserve integrity for years.

Over time, well production can decline or even stop from an accumulation of liquids in the well. Foamers can be used to remove these liquids and extend the production life of wells.

Injected via an SiA chemical injection pump at very accurate rates, foamers reduce the density of liquids accumulating in the well, making them easier to bring to the surface and allowing production to flow.

Foam can be generated from contaminants in fluids, from aeration of fluids and from depressurisation of fluids.

Injected via an SiA chemical injection pump at very accurate rates, defoamers act to destabilise the bubbles within the foam and/or stick to any foam-creating contaminants, preventing them from generating foam.

Hydrogen sulphide is a naturally occurring gas that is highly toxic, corrosive, flammable and explosive.

An SiA chemical injection pump is able to continuously inject accurate levels of chemicals to remove hydrogen sulphide gas from process systems.

Oxygen corrosion is most commonly caused by the injection of fluids from the surface that have been open to air for any length of time.

Injected at very accurate rates by SiA chemical injection pumps oxygen scavengers can mitigate the effects of oxygen in oil and gas applications.

Different types of scale formation can result from a wide range of factors including environmental changes – pressures, temperatures and PH levels; areas where sour gas is present; and areas where oxygen has been introduced.

SiA chemical injection pumps can deliver accurate dosing of scale inhibitor chemicals to minimise scale deposits on equipment, maintain production and increase the overall life of the well.